Application of Polymer Carbonizing Resin Plate

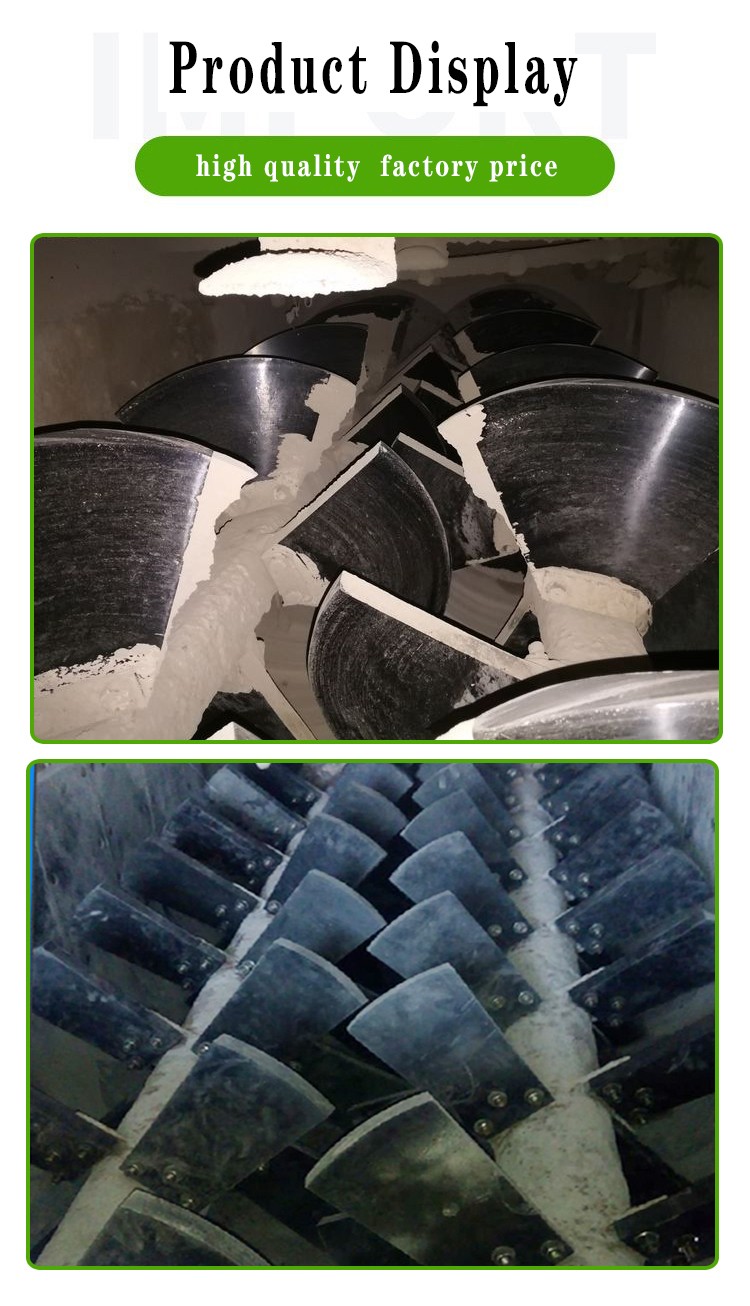

Humidifying cement mixer is in the process of running, the ash powder because of the humidity is big, easy to adsorption to the mixer of the warehouse wall, on the blades and the spindle, and solidifies into pieces, form the ingot "cement", the resulting a series of problems: 1. main shaft and blade bond as a body, form a very thick "axis", increase the machine load, motor overload; 2. The accumulation and solidification of ash powder in the mixer causes the effective volume of the mixer to decrease and the output cannot meet the working requirements; 3. The "cement ingot" formed by the solidification of ash powder forms a "grinding wheel", and extreme friction occurs between the blade, resulting in the blade wear too fast, the service life of the blade is too short, and the equipment maintenance cycle is short; 4, due to the ash powder adsorp tightly, clean up is difficult, due to the above reasons, in the process of the running of the machine, the workers have to spend a long time to knock the mixer blender wall and spindle, as time passes the equipment damage, and the operating workers labor intensity, low production safety coefficient, seriously hindered the normal ash removal work.

Polymerization resin board is a kind of carbide,are difficult to stick with wear-resistant material,with a very low coefficient of friction with other engineering plastics incomparable wear-resisting,self-lubricating,nonsticking materials,impact resistantce,corrosion resistance,non-absorbent,easy construction and so on comprehensive performance.It almost focus on the characteristics of all kinds of plastics,low friction coefficient,bibulous rate is almost zero,with only 1/8 of the steel,the quality of the volume is 1/7 of the 45#carbon steel,has a long service life.

After the modification of the humidifying mixer

1. After modification,the internal cement and ash accumulation of the mixer were solved.

2. Frequent blade replacement of agitator is solved.

3. The speed of discharge of agitator is slow and the efficiency of discharge is improved.

4.Ensure that the main parts,driven shaft,driving shaft,central shaft,reducer,motor and base of the mixer are not damaged by internal ash accumulation.

5.To improve the reliability of the equipment,there is no high material level in the ash warehouse,so as to ensure the safe and stable operation of the power plant.

- Previous:Nylon Roller

- Next:High molecular weight polyethylene manufacturers