Selection of silo lining board

At present, in power plants, steel mills, coal mines and other various silos, in order to prevent the bonding of materials, arch bridge and lead to the material is not smooth, blocked silo, generally installed in the silo lining board.Lining board types are: cast SLATE, microcrystalline board, nylon board, stainless steel board, ultra high molecular weight polyethylene board (UHMW-PE) and so on.However, because the manufacturers do not know the advantages and disadvantages of various lining boards, it is often difficult to buy what kind of lining boards is a good conclusion.Therefore, according to our years of practical experience in the service of chemical enterprises, we solemnly recommend to you: the choice of ultra-high molecular weight polyethylene lining board as a variety of silo lining board, is your priority choice.At this conclusion, we make a comparative analysis from the following aspects, for reference only.

First, the selection of raw materials and molding process of various lining boards, as well as the location of some manufacturers.

1. Casting SLATE: this product is made of some mineral soil raw material, which is melted into liquid at high temperature, poured into blank plate, and then polished into shape.Its manufacturers are mostly concentrated in the areas where there are raw materials for producing ceramic products.

2, microcrystalline plate: this product is the use of quartz sand after smelting extraction of glass, the remaining slag liquid pouring into blank plate, and then grinding finishing molding.Its manufacturer is currently the Xingtai glass factory next to one.

3. Nylon board: this product is a kind of raw material called "oil-containing nylon" in the nylon class, which is heated and melted into a liquid state, and then poured to be pressed into shape.As far as we know, there are only two.One in Tangyin, Henan, and one in Zhangjiakou, Hebei.

4, stainless steel plate: choose the stainless steel plate sold on the market as the lining material.It can be welded directly without forming.It is sold in all regions.

5, ultra-high molecular weight polyethylene board: is the selection of polyethylene plastic in all aspects are better, the relative molecular weight of more than 1.5 million ultra-high molecular weight polyethylene as raw material, because of the lower limit of the molten state flow speed is equal to zero, can not be extruded, can not be injection molding so only by calcination molding.There are not more than 100 chemical manufacturers, mostly in Tangyin, Henan.

6, other: in addition to the above five kinds of regular liner on the market at present, there are all kinds of plastic plate, the plate, they, in the foreign sales are generally in "ultra-high molecular weight polyethylene lining board" or to referred to as "the banner of" polymer lining board ", induced by the user, the user mistaken for ultra-high molecular weight polyethylene liner.In fact, these are fake and shoddy products, they use recycled plastic or such as: ordinary polyethylene, polypropylene, polyvinyl chloride and so on can not be used as the lining of the raw materials, after extrusion processing molding, disrupt the market, snare users.

On the above mentioned, we seem to not see the pros and cons of various material lining, but from the choice of raw materials, molding way and the number of manufacturers, we are not difficult to see the choice of nylon board, ultra-high molecular weight polyethylene board, stainless steel plate as the use of lining board without doubt.

1, cast SLATE, microcrystalline plate: the installation method of these two materials is almost similar, are made of chemical raw materials into adhesives, the inner wall of the installation mother can be cleaned, bonding on the lining plate.Its stick up the stick up method that craft and wall face brick do not have too big distinction.The installation process of this kind of liner has the advantages of convenient pasting, labor saving and time saving, and fast pasting.Defects are: first of all, because of the installation of the mother, liner and adhesive is not a material, its thermal expansion and contraction coefficients are not the same, so with the change of temperature in the four seasons, easy to lead to the split of the adhesive carrier and binder, produce the phenomenon of falling off the plate.When the lighter liner passes through the equipment below, the equipment will pass without injury, and the heavier one will damage the equipment of the next process.Secondly, because it is pasted to the lining plate mother, so after the end of installation, it generally needs about 15 days of solidification cycle.If the enterprise is in urgent need of to want to start production immediately, because can solidify period is less than and be forced to delay production, affect enterprise benefit.

2, nylon plate, ultra-high molecular weight polyethylene plate and other plastic lining board: this installation method, three kinds of products are bolted, just put in the metal silo lining plate, using a special countersunk head bolt, in a concrete bunker, pack lining plate is using a special countersunk head bolts, special environment is to bolt welding in the warehouse wall, and then the lining board mount fixed.

The advantage of ultra-high molecular weight polyethylene liner is: can need according to the actual installation site environment, any cut the shape and size of plate, and can make use of the flexibility of the ultra-high molecular weight polyethylene liner, in small radian of lining plate need environment, will be made certain radian, lining board flexed Israel casual line everywhere in the bin.

Advantages of nylon lining board: it and ultra-high molecular weight polyethylene lining board, can be arbitrary cutting, but it is cast molding, material nature is doomed to its hardness, can not be bent.

Other plastic lining board: for this kind of lining board we do not discuss more, because it is not in the sale of the true face of the people, they provide the product technical parameters, are generally the same as the ultra high molecular weight polyethylene lining board.Its only advantage is that the raw materials are surprisingly cheap.

Another advantage of plastic liner is that it can be used at any time when production needs to start, as long as equipment and personnel are removed from the installation site warehouse.

Disadvantages are: the installation of labor intensity of workers, long installation process.

3, stainless steel plate: the installation method is welding, the advantage is convenient installation, after the installation of the overall connection effect is good.Defect is: if it is in the original capsule based on technical renovation, so during the installation, installation of warehouse all parts must be welding welding points, so that welding with lining board, so the installation surface of capsule and there will be some space between the lining board, so the installation does not end cannot be put into use, such as the need to change, remove the difficulty is big, the high cost.

It is not difficult to see, as far as the installation process is concerned, the choice of plastic liner is the best choice.

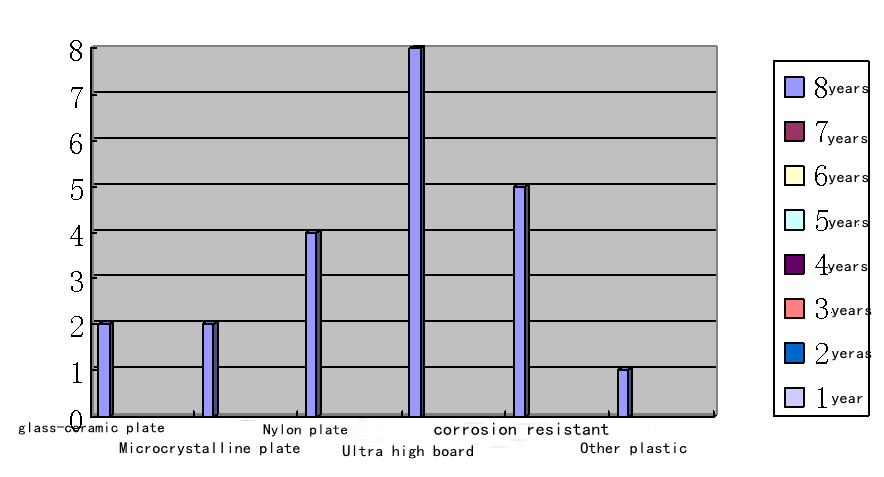

The third, the service life of various lining boards.

As shown in the figure:

Figure 2 the service life of various lining boards

1, cast SLATE, microcrystalline plate: because of the specific factors of its material, manufacturing process and installation method, the impact resistance is determined to be poor.When there is a large material impact, it will fall off and collapse, plus with the change of temperature difference in the four seasons, the coefficient of thermal expansion and cold contraction is not the same, it will also produce liner falling off.Therefore, its service life is generally not more than two years, even if the manufacturer did not find that the actual has fallen off.For example, the train coal unloading ditch in the coal conveying system of Foguang Power Plant of Shenhuo Group in Shangqiu City, Henan Province began to fall off within less than a year after it was lined with microcrystalline plates, and the plates stuck to coal.Another example: the ground coal hopper under the train dumper of Sinopec Shell Coal Gasification Co., Ltd. in Yueyang City, Hunan Province, was lined with cast SLATE at the beginning of construction. After six months of production, due to the serious and frequent drop of the board, it had to use ultra-high molecular weight polyethylene board.2, nylon board: the full name is "oil-containing nylon lining board", the characteristics of the material, determines that it can only be poured into shape, and the plate hardness is high, not easy to bend.If it is used as a lining plate in the silo under the condition of mud, the effect is particularly good.However, when used in other places, because of its poor flexibility, not impact resistance, coupled with the high coefficient of thermal expansion and cold contraction, so when used in the non-mud environment in the silo to do the lining board, fragile, easy to crack, easy to drop the phenomenon of the board frequently occurred.Moreover, with the change of temperature difference in four seasons, expansion and contraction lead to the expansion of the bolt hole fixed on it, so that the lining plate falls off.Such as: Guodian Guizhou Anshun Power Generation Co., Ltd. in the early stage of the plant, the choice of nylon board as the lining board, use less than a year, because of the frequent drop of the board affects the production, had to be completely removed, replaced with ultra-high molecular weight polyethylene board.

3, stainless steel plate: the characteristics of the material to determine the lining in the silo is not easy to rust, not like steel plate because of rust and hanging material.However, because of its high water absorption performance, no aging resistance, in the process of use, often because of water absorption and hanging material, bonding bin.With the transition of time, the lining surface will produce salt-like aging phenomenon, leading to the surface is not smooth, hanging phenomenon occurs, its service life is generally between 3 ~ 5 years.For example, the Zhejiang Jiangshan Chemical Plant self-provided power plant, in the original coal bunker to the coal slit lining 5㎜ after the stainless steel plate, three years of lining plate surface produced salinized aging phenomenon, often hanging coal, resulting in coal is not smooth, had to be removed, replaced with ultra-high molecular weight polyethylene board.Another example: Hunan Datang Huayin Jinzhushan power plant coal conveying system car unloading ditch equipped with 5㎜ after the stainless steel plate, due to water absorption led to the coal is not smooth.

4, other plastic board: actually choose waste plastic or ordinary polyethylene, polypropylene, polyvinyl chloride and other materials extrusion molding liner.This kind of product has low hardness, soft material, low melting point, poor impact resistance, high coefficient of thermal expansion and cold contraction. These deficiencies definitely tell us that this kind of product can not be used as lining board in silo!However, because some manufacturers by the interests of the drive, coupled with the user often at a low bid conditions, prompting them to hang sheep's head to sell dog meat, the use of customers on the lining board is not very understanding, to replace the real, with other materials instead of ultra-high molecular weight polyethylene material, disrupt the market.To be honest, all kinds of plastic lining board can solve the phenomenon of material stickiness, but the length of the use of time, the quality of the use, it is very different.There are some duped manufacturers using this kind of liner, less than a year there will be a large number of damage and drop plate phenomenon.Its normal service life generally will not exceed half a year.

5.Because of its relative molecular weight in more than 1.5 million (ordinary polyethylene molecular weight in 20,000 ~ 300,000, polymer polyethylene molecular weight in less than 800,000), has the advantages of impact resistance, non-water absorption, self-lubrication, non-bonding foreign matter, thermal expansion and cold contraction coefficient is small and so on, it has been widely used in a variety of silos, hopper lining plate use,As long as the installation is in strict accordance with the installation process and operating procedures for construction, its normal service life in ten years or so, no problem.Such as: Huaneng Yimin Power Plant (Hulun Buir, Inner Mongolia), Shaanxi Qinling Power Plant, Yueyang Baling Petrochemical Self-provided Power Plant and many other enterprises, the use of ultra-high molecular weight polyethylene board in the original bunker life has been more than 10 years.

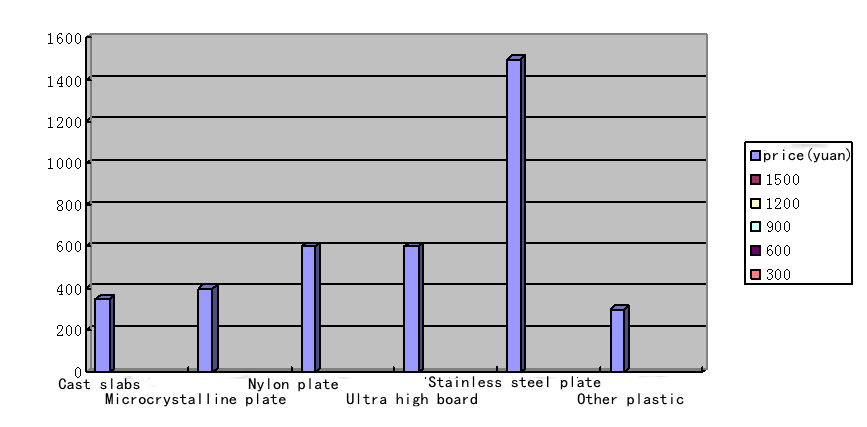

The forth, the price comparison of various lining materials:

Figure 3 Price comparison of various lining boards (Yuan /㎡)

Note:

1, all lining are used in the same environment, plastic lining according to δ=15㎜, stainless steel according to δ=5㎜ quotation.

2. The price shown in this price comparison table is the average price and the competitive price in the market over the years. It is not used as the basis for price.

3. The quotation of other plastic lining boards either starts at a low price, or follows the quotation of ultra-high molecular weight polyethylene lining boards and nylon lining boards, and the result is always that it is cheaper.

In short, after the comparison of all kinds of lining boards, from the choice of raw materials, installation process, the length of service life, price comparison and other four aspects of the demonstration and analysis, there is no doubt that ultra-high molecular weight polyethylene lining board is worthy of choice of lining board.