TangyinHongda Successfully Developed Blades of Wetting Mixer in Ash Storage of Power Plant

Polycarbonized Resin Blade for Ash Storage Humidifying Mixer in Power Plant

Name: Polycarbonized Resin Blade of Mixer

Specifications: Customer Requirements

Performance:

1. Difficult to bond and self-lubricate. As we all know, the blade of mixer often causes serious sticking and is not easy to clean because of the ash moisture content during use. This material has excellent non-cohesive and self-lubricating properties, its water absorption is 0.01-0%, and friction coefficient is 0.07-0.11.

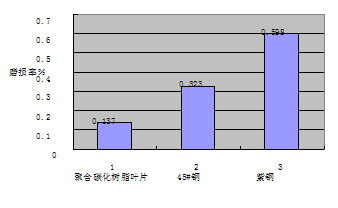

2. Polycarbonized resin blades are wear-resistant and have long service life. (See figure below for details)

3. The product is light in weight, reduces resistance of motor, saves energy and reduces consumption. The weight of this product is only about one-seventh of the metal blade.

4. Corrosion resistance. The blade can stand in most kinds of corrosive media and organic media (except tea solvent) within a certain temperature and concentration range. There is no physical change in the product even if it is soaked in more than 80 organic solvents for 30 days .

5. Low temperature resistance. The blade has excellent low temperature resistance and ductility at - 269 ℃, so the use of this product in winter will not affect its use effect at all.

6. Impact energy absorption. The blade has excellent shock absorption and silencing-performance, so it has low noise when used.