Test Research on Friction and Wear of New Sealing Structure Polymer Roller

Summary: A roller testing machine is designed and fabricated in this paper. The friction and ware test of a new high polymer roller is carried out on this testing machine. Compared with a general steel roller, a conclusion is drawn that new sealing structure nylon roller has many advantages such as little power consumption, little wear, long application life, good economics, etc.

Key words: High polymer roller; friction and wear; testing machine

The Roller with usage large amount and frequent replacement is one of the key parts that affect the use effect of belt conveyor machine. Account for 30% to 40% of the total weight, 25% to 30% of the total price. Due to the poor working conditions and mechanical structure of itself, the traditional idler/roller has a different degree of easy corrosion, heavy weight and non-wear resisting. Our factory has test the new-style idler/roller which was designed of multi-layer seal structure and was made of high molecular weight polyethylene, for the experiment to be closer to reality, we designed a test sealing machine, and did the test on the friction and wear experiments of idler/roller.

The Designing of Idler/Roller

The "heart" of the roller is the bearing, and the best way to protect the bearing is to improve and strength the sealing structure. The failure of the roller is the bearing failure that is due to the poor sealing effect, which makes the dust and other pollutants entrance successful. If the seal structure of the idler/roller can be waterproof and dust-proof, it can guarantee the lubricating effect of grease for a long time. Therefore, the actual effect of the idler/roller is determined by the sealing effect.

The new style idler/roller is a patented technology; the body of idler/roller adopts wear-resistant engineering plastics: nylon, ultra-high molecular weight polyethylene, etc. The sealing structure adopts multi-layer seal, which increases the waterproof seal (cushioned seal) and the additional dust-proof seal than the normal sealing structure. In addition, the sealed idler/roller bearing is also chosen. This triple seal structure can be used to achieve the effect of waterproof and dust-proof. The concrete supporting roller structure is as follows:

The Test Platform

The Y90l-2 motor produced by Hengshui Motor Co., Ltd was finally selected. The rated power of the motor is 2.2 KW, and the rated speed is 2835 r/min. The actual rotating speed of the test bed is 496 r/min, and the linear speed is about 4.13m/s.

We bought some metal idler/rollers for a machinery factory production in Hebei, code: Φ 159 mm x 465 mm x 16 mm as reference for comparison.

Principle of experiment counting

In the test, the idlers/rollers accumulative run 60 hours and 7 seconds and the steel idlers/rollers run 60 hours and 9 seconds. The test data were read at 10-20 hours in the test machine.

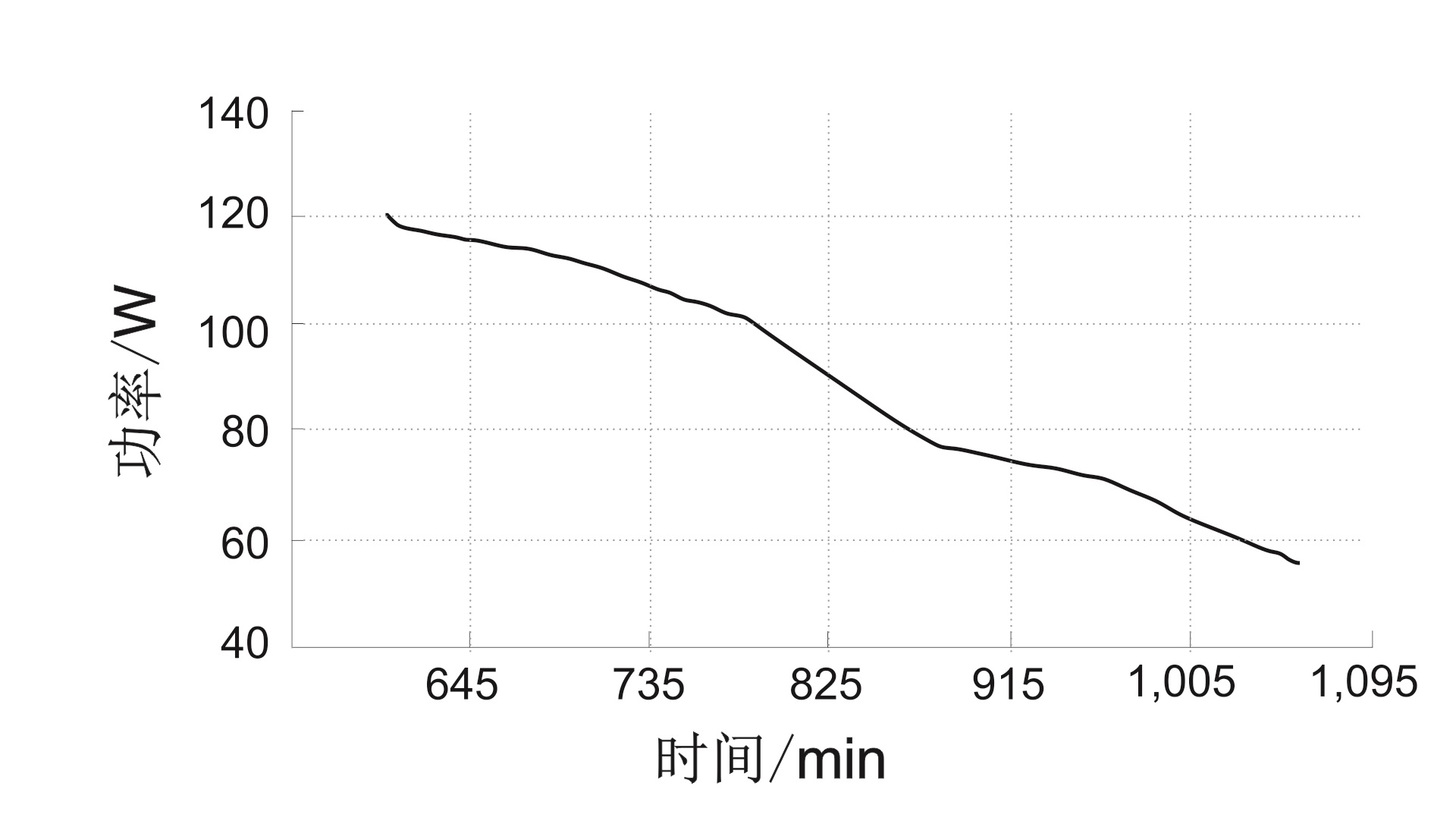

Average power curve of Nylon Idlers/rollers Average power curve of Steel Idlers/rollers

Comparing the two graphs, the power consumption of the nylon roller is lower than that of the steel roller. In the same working time, the belt conveyor with nylon roller is less energy consumption than the belt conveyor with steel roller.

Wear & Tear Capacity

The wear & tear capacity of the idler/roller is the difference between the diameters of the roller has operated for a while and the diameters before the test.

The diameter of the roller is measured at the center of the roller length and the two sides of the distance center 70 mm and 140 mm. The diameter of the above five points was measured before the roller test was started. After the experiment, the diameter of the above five positions were measured again. The results of wear of nylon roller and steel roller are shown below:

Test No. | 1 | 2 | 3 | 4 | 5 | Average |

Wear & Tear of Nylon Roller / mm | 0.06 | 0.06 | 0.02 | 0.02 | 0.22 | 0.036 |

Wear & Tear of Steel Roller / mm | 0.08 | 0.02 | 0.04 | 0.08 | 0.08 | 0.060 |

The upper table can be reached: within the unit time, the wear volume of the nylon roller is less than that of the steel roller.

Epilogue

1. In the normal operation of belt conveyor, the power consumption of nylon roller is much lower than that of the steel roller, and the average power consumption is decreased by 28.3%.In the same time of use, the use of nylon roller to replace steel roller can greatly reduce the operation cost of belt conveyor.

2. The wear volume of the nylon roller is less than that of the steel roller, and the average wear amount is reduced by 40%.Therefore, in the same working condition, the service life of the nylon roller is greater than that of the steel roller.

3. This new sealing structure polymer roller has the advantages of small operation power consumption, long service life and low maintenance cost, and has high economic applicability.