The transport characteristics of tubular belt conveyor and the selection of relevant roller

With the rapid development of science and technology, the modernization is becoming more and more advanced. The production site urgently needs the large cut Angle, bend belt type conveyor, to improve the automation degree of continuous transmission, and also demand the establishment of a new pollution-free transport good working environment. Tubular belt conveyor has been used domestic and overseas at present, which basically has the follow several kinds of models: hanging wheel, guide rail type, natural circle tubular and powerful circular tube shape belt conveyor, etc.

Characteristics of tubular belt conveyor:

1. It can be widely used in continuous conveying of various materials

According materials it was divided into several types:

(1) Lumps: coal, limestone, etc.;

(2) Particles: fine sand, salt and sugar;

(3) Powder: cement, flour, etc.;

(4) Liquid substance: butter, etc.

2. Environmental protection function

Tube machine in the operation of the conveyor belt into tubes, the two sides have certain lap length, the material is not easy to float in the sky scattered two-string fiddle consumption, also won't be affected by the external environment (such as wind, rain, etc.), especially when carrying powder, chemical products, food, the superiority is more significant, at the same time, due to the conveyor belt during the transition period of repeated deformation, can remove and prevent adhesion material on the conveyor belt. Therefore, the transport block, powder, toxic and dust materials will not cause external environmental pollution.

3. Energy saving features

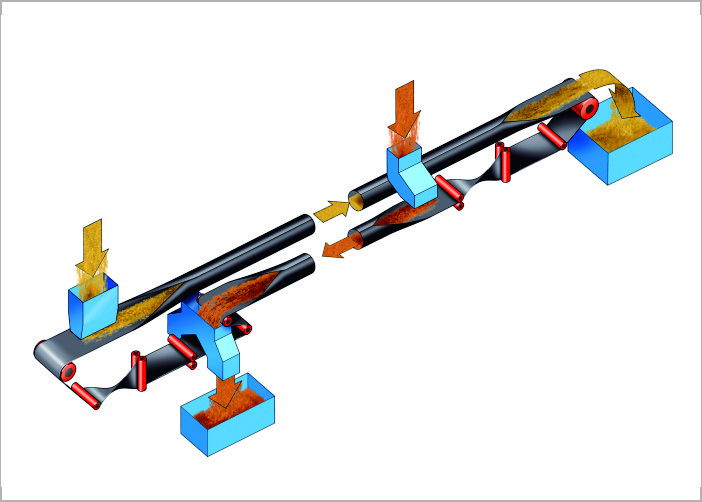

Tape was six roller forced into circular tube shape, without conveyor belt running deviation, tube machine can realize three-dimensional spiral is bent, a tube shape instead of a belt conveyor which is composed of more than ordinary belt conveyor system. Savings in civil construction (transfer stations), equipment investment (reducing the number of driving devices), and reduced failure points, equipment maintenance and operating costs. The tubular belt conveyor comes with the corridor and prevents the influence of rainwater on the material. Therefore, after selecting the tubular belt conveyor, it can no longer build the trestle bridge and save the cost of the trestle. Due to the tubular shape of the conveyor belt, the common belt conveyor with the same width of the truss is narrow, and the cover and expense are reduced.

4. Small radius bending, large Angle tilt ability

5. Transported matter by round trip and large transport capacity

Characteristics of special roller for tubular belt conveyor:

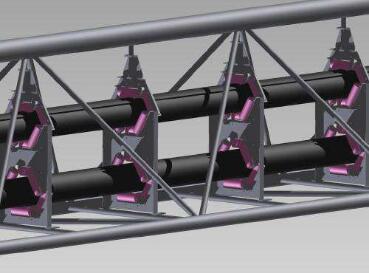

1. The conveyor belt is forced into a circular tube by six rollers, so the Angle of the special roller of the conveyor is not free to adjust.

2. The design position of the roller group is not the most reasonable position in the process of use, which needs to be rectification according to the actual situation of the conveyor belt.

3. The installation location is not the most reasonable position and the most reasonable Angle of the conveyor belt, the compression resistance of the corresponding belt will increase, then the running resistance of the conveyor belt will be increased.

4. The grooved roller group cannot make the flat conveyor belt overreach the circular tube in the state of natural flow, and the range of belt tension will become larger, leading to the decrease of its service life.

Above all, ordinary belt conveyor in the Angle of the slot type roller group will increase the conveyor belt running resistance, pressure resistance, increase of belt tension range, at the same time increase the cost of ordinary belt conveyor design, installation and debugging cost money.

Hongda's solution:

After a lot of spot tests and customer feedback, the mothed through special adjustable groove type tubular belt conveyor roller group to solve above problems, can effectively reduce the conveyor belt running resistance, sag resistance, and reduce its tension range, save users money.

The specific scheme is: adopt the special structure composed of sliding mechanism, roller group, and bracket and adjustment mechanism. The roller group consists of three rollers, the middle roller is mounted on the bracket, and the two rollers are adjusted by the adjustment mechanism. In a rack set up six circular tube type conveyor belt roller lift, six roller in the cross section of circular tube belt round into circular direction, the bottom edge of the three roller set on the roller frame, the top three roller set in a baffle on the shelf, baffles are capable of opening and closing of hinged on the roller frame. The two sides of the baffle frame are connected by a torsion limiter and a bracket. The sliding mechanism is placed on both ends of the bracket to adjust the positioning of the bracket by adjusting the sliding mechanism. When in operation, according to the conveyor belt from 35 degrees Angle of groove type transition to circle tubular shape dynamics of change, to change the installation location and flexibly control the Angle of roller, can ensure that the conveyor belt natural smooth transition to the circular tube, thus reduced the scope of the change of the conveyor belt tension, extend the life span of the conveyor belt.